The journey from laboratory breakthrough to market implementation represents one of the greatest challenges in bioplastic innovation. Exploring Dr. Federica Bertocchini's experience reveals how we might bridge the gap between scientific potential and industrial application for truly regenerative solutions.

The journey from laboratory breakthrough to market implementation is often described as crossing the “valley of death”—a perilous transition where promising innovations frequently falter. Nowhere is this challenge more evident than in bioplastic innovation, where scientific breakthroughs face numerous hurdles on their path to market adoption. Dr. Federica Bertocchini’s experience with enzymatic degradation of polyethylene offers valuable insights into these challenges and potential pathways forward.

The Innovation Gap

Dr. Bertocchini’s discovery—enzymes from waxworms capable of degrading polyethylene—represents the kind of breakthrough that generates headlines and sparks hope. Yet as she candidly shares, transforming this discovery into a scalable solution has proven tremendously challenging.

“If you talk with industry, any kind of industry, generally speaking, they want a solution in six months,” she explains. “They want a solution in a way that you close the cycle.”

This fundamental disconnect between scientific timeframes and business expectations creates an innovation gap that many promising technologies struggle to bridge. Scientific research, especially in emerging fields, typically requires years of development, refinement, and testing. Industry partners, meanwhile, often operate with quarterly targets and expect rapid returns on investment.

Competing with established systems

A key challenge for bioplastic innovations is the entrenched nature of existing plastic production and waste management systems. These established systems benefit from decades of optimization, extensive infrastructure, and economies of scale that new approaches simply cannot match—at least initially.

“Can you go cheaper than burning?” Dr. Bertocchini recalls being asked about her enzymatic solution. “Burning you have to take into account the infrastructure…but even the fact that you consider burning a solution, for us it’s difficult.”

This comparison to incineration highlights a critical issue: innovative solutions are often evaluated solely through the lens of current economic frameworks, without adequately accounting for externalized environmental and social costs.

The funding challenge

Perhaps the most immediate barrier for bioplastic innovations is securing adequate funding through the development phase. As Dr. Bertocchini notes, her team relies primarily on “public competition, startup…we are talking about a few hundred thousand euros for a couple of years.”

This level of funding, while helpful, falls dramatically short of what’s needed to scale promising technologies. The contrast with established industries is striking: “Looking at the numbers of these industry, numbers that they publish in terms of revenue, I’m astonished…we get 200,000 euros as an example. So for two years, let’s see what we can do with that. It’s ridiculous to think about that.”

Without substantial investment, promising technologies remain perpetually in development, never reaching the scale needed for meaningful impact.

The cultural gap

Beyond financial and technical challenges lies a deeper cultural division between scientific research and industrial application. Dr. Bertocchini describes entering “a landscape which is terrible, because it’s a competition, one against each other instead of getting together and trying to” collaborate.

This competitive environment extends beyond academia to the relationship between research institutions and industry. Different priorities, communication styles, and success metrics create friction that impedes effective collaboration. As she notes, “You had the academic world, which is not necessarily better than the industry. A different set of people, a different set of people with different minds and rarely they cross paths.”

Changing paradigms

Despite these challenges, there are pathways forward for bridging science and industry in bioplastic innovation. Several strategic approaches could help bridge these divides:

1. Embracing complementary solutions

Rather than positioning bio-based approaches as competitors to existing methods, framing them as complementary can reduce resistance and create space for collaboration. As Dr. Bertocchini observes, “They always put you on a competition recycling versus bio versus chemical. Actually, no, it’s not a competition. We need all things together. Again, generally speaking and then the investor feeling maybe they want to invest in one or the other, but do we need more than one? That’s how I envision the picture.”

This integration of approaches recognizes the complexity of plastic waste and allows for targeted solutions based on specific contexts and material types.

2. Rethinking value metrics

Expanding how we measure value beyond immediate economic returns could help justify investment in longer-term innovations. This might include developing standardized metrics for:

- Reduction in microplastic pollution

- Decreased carbon emissions compared to conventional disposal

- Recovered material value from waste streams

- Health impacts from reduced plastic persistence

These broader value considerations could help bridge the gap between scientific potential and business requirements.

3. Creating innovationecosystems

Successful bioplastic innovation likely requires coordinated ecosystems rather than isolated efforts. Dr. Bertocchini envisions “a whole” approach involving “different parts of society, different involvement…being aware of where we are going, what we are doing, what solutions we might have, and the path to where to run, where to walk plus the science.”

Such ecosystems might include:

- Academic research institutions developing fundamental knowledge

- Startups focusing on specific applications

- Established companies providing scaling expertise and market access

- Government agencies setting supportive policy frameworks

- Civil society organisations creating demand and awareness

4. Patient capital and blended financing

Innovative financing approaches could help bridge the funding gap for promising technologies. “Patient capital” with longer investment horizons and blended finance approaches that combine public and private funding could provide the sustained support needed for complex bioplastic innovations to reach market readiness.

The path forward

The challenges in bridging science and industry for bioplastic innovation are substantial but not insurmountable. As Dr. Bertocchini’s journey illustrates, persistence and a clear vision remain essential. Her request—”a team of 10 people and $5 million for the next 2 years”—represents a modest investment relative to the potential impact of advancing enzymatic degradation solutions.

With this support, she aims to “produce the enzymes on a large scale, reduce the cost as much as we can, optimize them, and have solutions for the degradation product, like the way to extract them and how to use them.” This targeted, achievable plan illustrates how complex innovations can be broken into manageable steps with clear deliverables.

Towards a regenerative vision

Ultimately, bridging science and industry in bioplastic innovation requires more than technical solutions or funding mechanisms—it demands a shared vision of a regenerative future where plastic is no longer persistent waste but a material that can be returned to useful purposes.

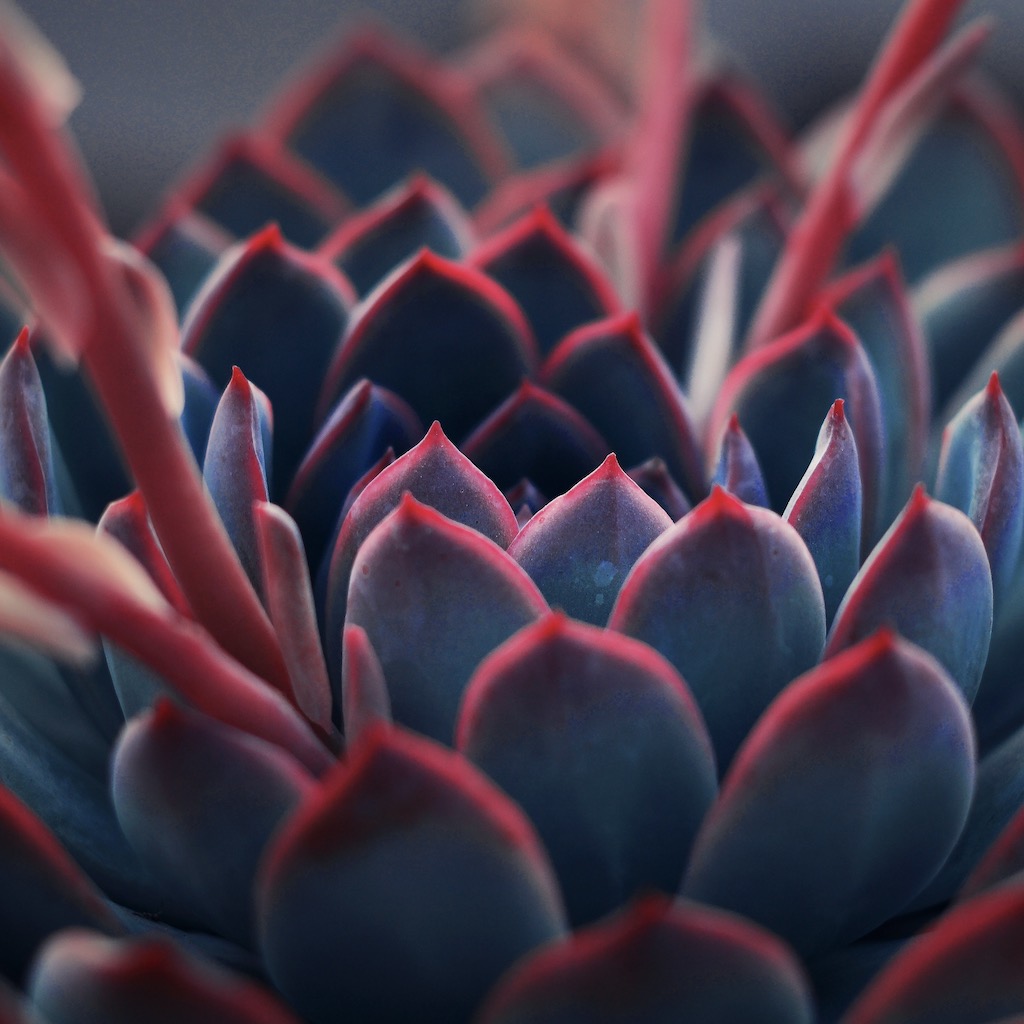

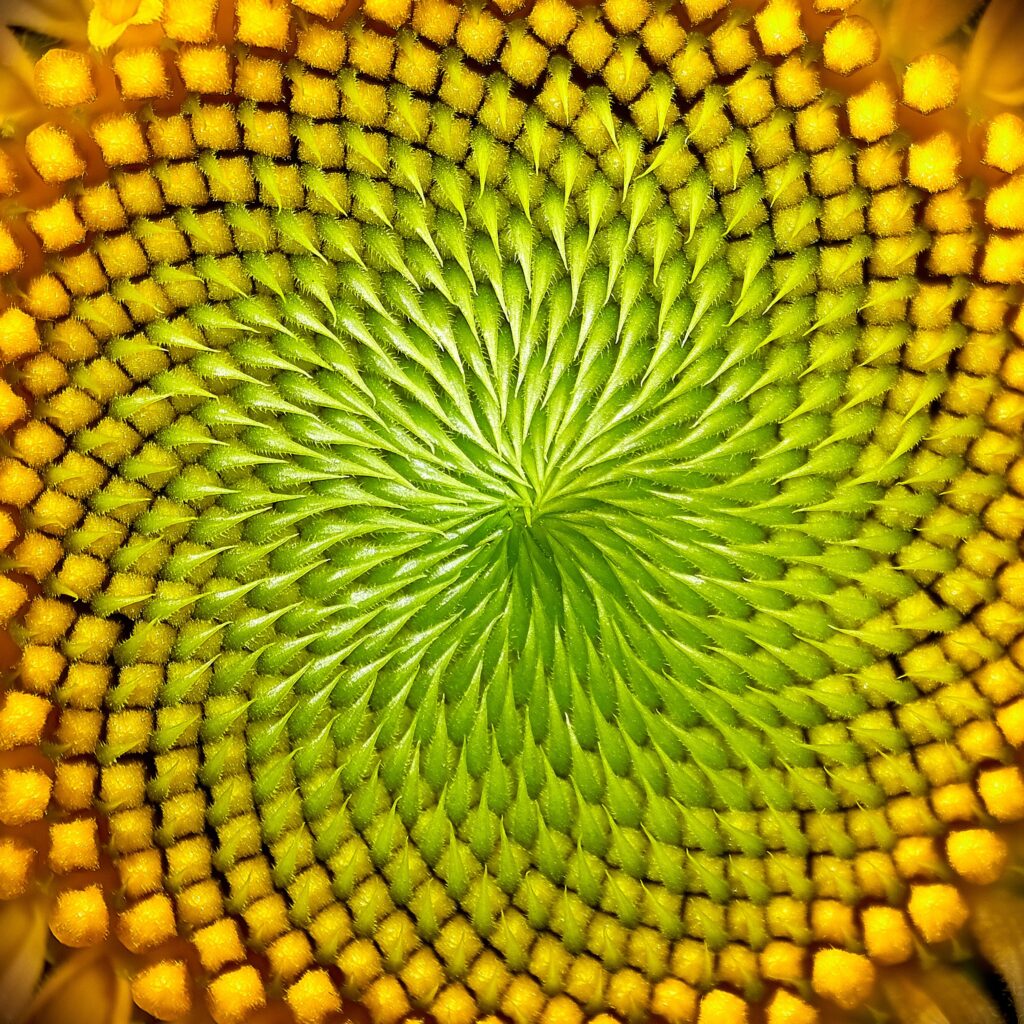

Dr. Bertocchini captures this vision when she speaks about nature’s example: “Nature is there, you give a solution that needs to be worked out, of course. It’s not straightforward, but we spent years, decades developing technology that might allow us to do that. So let’s use these technologies.”

This sentiment embodies the regenerative approach to plastics—looking to nature’s patterns and processes not just for inspiration but for practical solutions that can transform how we produce, use, and manage these ubiquitous materials.

By embracing this perspective and working to bridge the divide between scientific innovation and industrial application, we move closer to a future where plastic truly becomes part of regenerative cycles rather than a persistent environmental burden.

To hear more about her insights and ideas about the importance of nature in the future of PET and plastic, check out the full conversation on the adaPETation® Podcast.

LOOKING FOR MORE INSPIRATION?

The future of plastics is being redefined, and you can be a part of it. Listen to the full podcast with Dr Federica Bertocchini to delve deep into the regenerative path of PET.

Your support can usher in a new era where plastic, once the problem, becomes an integral part of the solution.

Share it

Useful Links

THE HISTORY OF PLASTIC

Throughout the history of plastic, PET has been crucial in keeping food fresh with lightweight and durable packaging solutions that have helped reduce food waste for almost a century. Learn all about the invention of plastic and the important role it has played feeding people and saving the lives of humans and elephants in the adaPETation® timeline of the history of plastic.