Making the right decisions regarding material use will be crucial as we seek to decarbonize so many different aspects of our lives in the next 30 years, and plastic – despite being demonized for issues surrounding waste – has a big role to play in getting to net zero and beyond.

While there are undisputed benefits to the world’s most easily recycled plastic including its life- and energy-saving properties, the most degenerative aspects of the polymers like PET still need to be addressed.

Plastic’s contribution to the degradation of our environment through greenhouse gas emissions and the accumulation of plastic waste in our ecosystems results from our collective inability to fully recycle the precious material.

For all the marvelous benefits the material has had on our lives, our inability to close the loop on its production is only too visible in viral videos like the one published by the Oceans Cleanup showing a tsunami of trash in Guatemala.

However, it will take more than a host of beach and river cleanup operations to bring the material into line with the needs of the planet. Turning off the plastic tap further upstream is a matter of extreme complexity that requires system thinkers to design for longevity instead of programmed obsolescence.

Those charged with implementing the UN global treaty to end plastic pollution signed in April 2022, will need to focus on organizations that are able to mimic nature and plug in to 3.8 billion years of research and development to address the complexity of our species’ interdependence with the material if they have any chance of success.

The complexity that surrounds the material with its positive and negative impacts on the environment is hard for many to grasp. It’s so much easier to simply dismiss the material of choice for the 20th century as the villain in our monumental battle to clean up our planet than to fully understand the place it has to play in solving perhaps the greatest challenge we’ve ever faced as a species.

The alarmist headlines of plastic replacing coal in terms as a producer of greenhouse gas (GHG) emissions in the US by 2030, have been held up by environmental activists as a disturbing indication that our interdependence with plastic is counter-productive in our fight to slow the worst impacts of greenhouse gases in our atmosphere.

But solving the GHG conundrum will require a fresh look at some of our societal biases, blindspots and misconceptions about the material

With so many complex systems intertwined in the merry dance that is co-creation of life on earth, a deeper analysis is required to make sense of the correct mix of materials that will help us in our species’ journey to reduce its collective carbon footprint.

Hidden Costs & Hidden Benefits

Over the past four decades, global plastics production has quadrupled creating a trend that if it were to continue, would plot the plastic industry’s GHG emissions on a path to reach 15% of the global carbon budget by 2050.

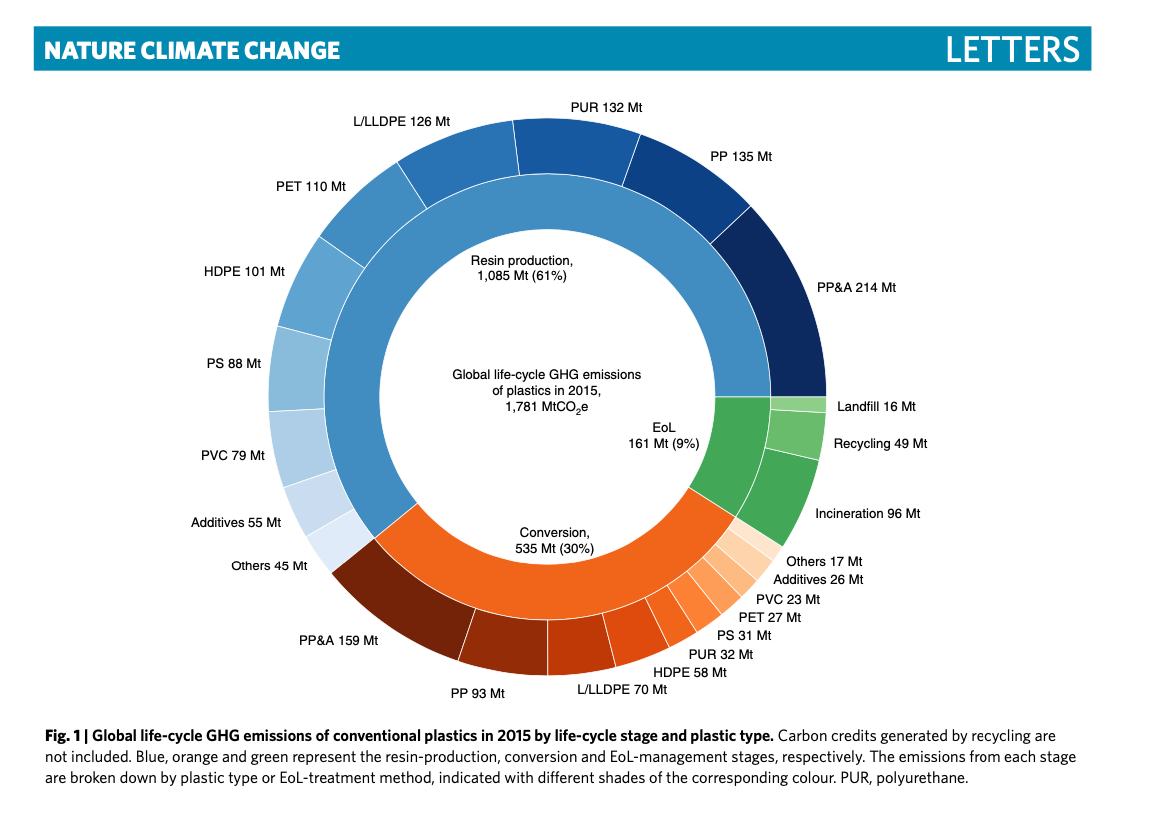

The most definitive studies put the plastic industry’s total GHG emissions at 1.7 Gt of CO2-equivalent (CO2e) in 2015, accounting for 3.5% of total GHG emissions of 47Gt of CO2-equivalent (CO2e), with carbon footprint forecast course to grow to 6.5 GtCO02e by 2050.

It’s estimated that PET and rPET accounted for 137m tonnes of CO2e, or 7.6% of the polymer industry’s total GHG emissions, according to numbers published by sustainability expert, Jiajia Zheng.

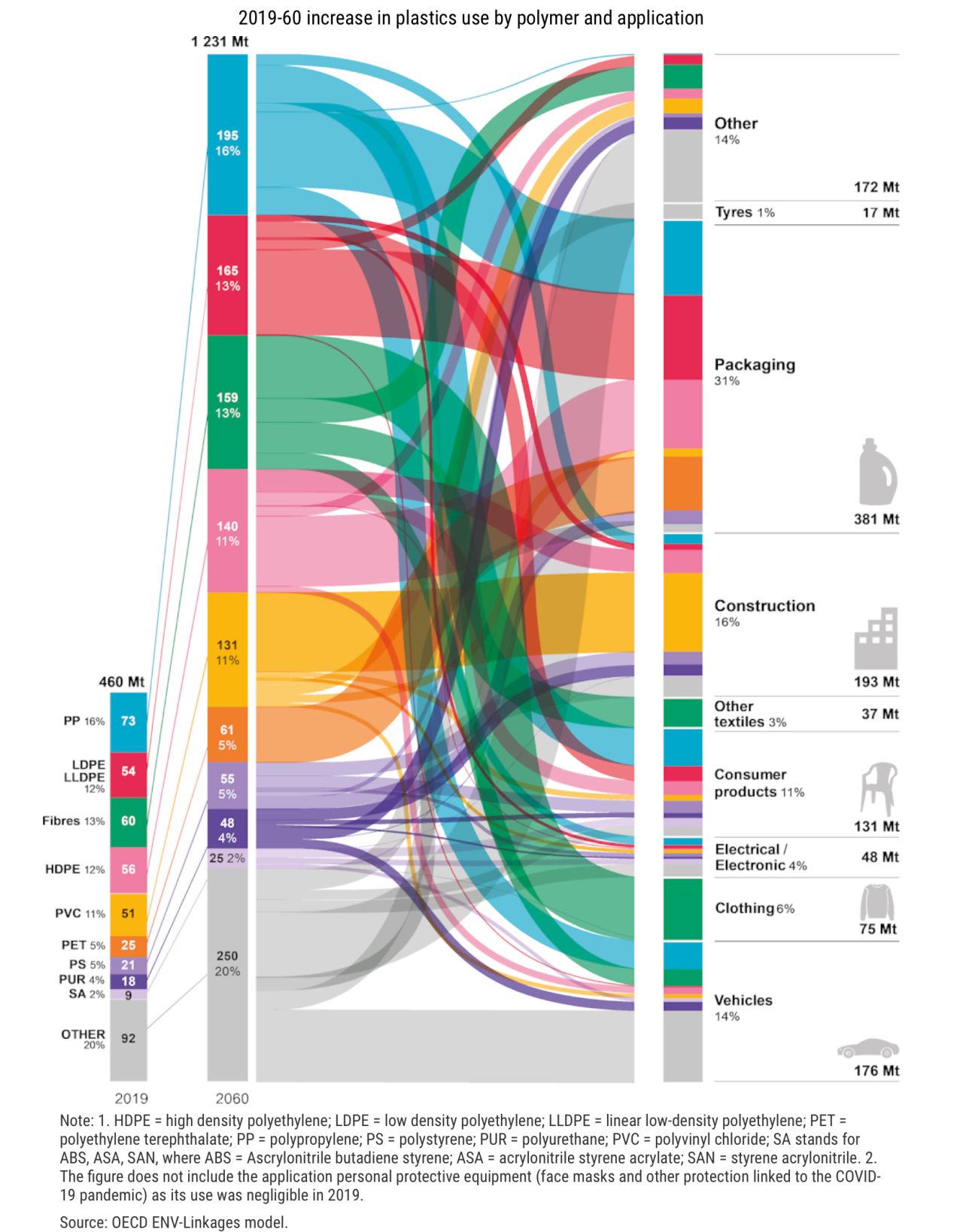

In 2019, PET used for packaging accounted for 25m tonnes or 5% of total plastic production of 460m tonnes, a figure that is expected to grow to 61m tonnes in 2060.

Besides the invisible but tangible effect of GHG there are other more all-too-apparent externalities associated with our use of the material in almost every aspect of our modern lives.

We collectively throw away $120bn of packaging a year, sending it to landfill or converting it into fuel and the not-so-hidden cost of poor waste management and inefficiencies in the recovery of this valuable material can be seen in $13bn a year in damage to the world’s oceans.

The industry’s waste problems make it easy to understand why plastic has come under fire for our collective failings in managing its end-of-life disposal and recycling. And yet, while there are many hidden costs there are also important hidden benefits associated with our use of the material.

Hidden benefits of the material include the energy savings that different types of plastics offer as a result of the materials efficiency and the use-phase emissions benefits of plastic (in particular insulation of buildings, light-weighting of vehicles, etc).

It’s estimated that vehicles are now almost 50% made of plastic with lightweight plastic components accounting for just 10% of the overall weight. A 10% reduction in weight delivers a 6%-8% saving in fuel consumption and thus plastic has helped cars become 10% lighter on average since 2003 (down from 1,100 kg to 1,000 kg in 2014).

What have we done with this saving? We’ve made bigger cars that have outweighed some of the gains afforded by plastic. The average car has increased in weight overall by 10% in the last 42 years.

Likewise lightweight plastic packaging reduces food waste and fuel consumption across the consumer goods industry and plastic insulation for housing provides significant energy savings in heating homes.

“Plastics are arguably among the most revolutionary materials humanity has invented. They are low-cost yet lightweight, durable, and highly customizable. However, one could also argue that plastic is now a victim of its own success, with increasing criticism of marine pollution, roadside litter, fossil feedstock use, and lack of recycling,” says Stefan Helmcke, senior partner at McKinsey & Co in its recent report, the Climate Impact of Plastics.

“There is one aspect of this conversation that has not received the attention it deserves: the environmental benefits plastics bring compared with alternatives, especially in relation to GHG emissions.”

The success of PET in replacing other less energy efficient materials like glass and aluminium for packaging has helped reduce the average GHG emissions for many items. The widespread adoption of plastic due to reduced costs and at a micro-level the carbon footprint of so many items has paradoxically, made it one of the areas of fastest growth in terms of overall emissions.

And yet it still remains small compared to other industries, some of which benefit greatly from lightweight plastics. Emissions from transportation for example accounts for 27% of GHG emissions (12.7 Gt of CO2e) and cement production used in construction accounts for 3.6 Gt of CO2e or 8% of global emissions.

To add further perspective, an industry producing 1.7 gigatons of carbon a year would need to plant 31 billion to 46 billion trees a year to offset its greenhouse gas emissions. Putting that number into context, the United Nations Environmental Program estimates that 1.9 billion trees are planted a year, according to the United Nations Environmental Program.

Even though we would be much worse off if plastic didn’t exist and we were using other materials in its place, the overall numbers have prompted a fervent lobby calling for the tap to be turned off upstream to halt the flow of plastics but how to do this without placing further pressure on our environment?

More Plastic Not Less Needed To Fight Climate Crisis

A much deeper analysis is required to make sense of which materials will help us on our journey to reduce our collective carbon footprint in the long-term.

While the simple conclusion appears to be a need to reduce our use of the material to fight global warming, there are studies that suggest quite the opposite.

A study published recently by consultants McKinsey & Co deliberately left the criticisms of plastic pollution aside to focus on the benefits of the material in keeping greenhouse gas emissions down across a wide range of uses.

“Among applications for which non plastic alternatives are used at scale, the plastics examined in this paper offer a lower total GHG contribution compared with alternatives in 13 of 14 cases,” writes Helmcke.

“GHG savings range from 10% to 90%, considering both product life cycle and impact of use. In addition, in many applications, particularly those concentrated in food packaging, there are few alternatives to plastics today. In fact, plastics adoption in the near term can help decarbonization efforts in these areas, particularly in terms of food spoilage and energy efficiency, given their lower GHG footprint.”

The latest study underlines findings made in 2014, by Trucost, that suggested that the environmental cost of plastic in consumer goods was 3.8 times less than viable alternatives to plastic like glass, tin, aluminium and paper and that substituting plastic in consumer products and packaging with alternatives would increase worldwide environmental costs from $139 billion to a total of $533 billion.

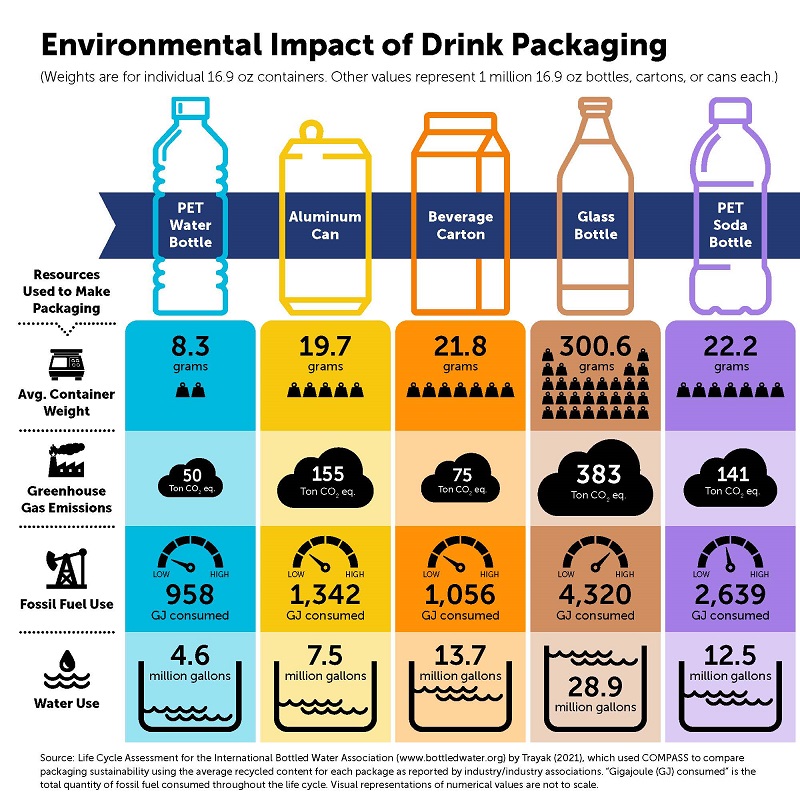

In the area of soft drinks, life cycle analysis (LCA) studies established that PET bottles have the lowest emissions because of their lightweight properties and the low amount of energy required to produce them. By contrast, aluminium cans generate two times the emissions of PET bottles, and emissions from glass bottles are more than three times higher.

The LCA studies used by McKinsey & Co indicated that a PET bottle produced in the US generated 435 kg of CO2e emissions per 100,000 oz of soft drink compared to 890 kg of CO2e emissions in the case of aluminium and 1,170 kg of CO2e emissions in the case of glass.

Plastic bottles would improve their performance even further if the industry could improve the recycling rate and channel more post-consumer waste back into the supply chain away from waste to energy plants and landfill. Greater circularity would help the industry break from its reliance on virgin fossil fuels.

“Although the PET bottle has the lowest production emissions, it has the least favorable GHG emissions for its end-of-life disposition. PET has the lowest recycling rate and credits from avoided virgin production among these three materials. It also has the highest emissions from waste to energy. (PET releases CO2 when burned, whereas aluminum and glass do not.) However, the GHG impact of production emissions is more significant than end-of-life disposition emissions, resulting in PET having the lowest GHG impact,” writes Helmcke.

End of life processes made up 9% of the global plastic carbon footprint in 2015 so increasing recycling of PET in the US, where it has a 17% market share in the soft drinks market compared to 60% for aluminium, will contribute even further in the fight against climate change, especially in the short-term as we transition to a cleaner energy mix.

McKinsey’s study highlighted the importance of the energy mix in different parts of the world as a key factor in the comparative advantage of PET over other materials suggesting that the decarbonization of the energy network in economies like China and India would help reduce significantly the difference between plastic and other materials.

The higher use of coal-fired power plants in China means that PET produces 67% less GHG emissions. In China, a PET bottle generated 550 kg of CO2e emissions per 100,000 oz of soft drink compared to 1,670 kg of CO2e emissions in the case of aluminium and 1,800 kg of CO2e emissions for glass.

Nearshoring of production to countries with cleaner energy networks and higher recycling rates like Europe and the US will help limit the GHG emissions associated with plastic in the short-term.

While major economies, China and India, shift towards a cleaner energy mix, PET has an important role to play in limiting our current carbon footprint as the least harmful material when it comes to greenhouse gas emissions.

Plotting a Path to Zero

In the long-term, PET and rPET plastic still has room for improvement if it is to put itself at the service of the planet and start delivering the reversal in carbon emissions that is needed.

The first step is to prevent plastic’s carbon footprint doubling from 1.7 Gt CO2e to 3.5 Gt before bringing the downward trajectory to zero, or even less.

Studies by the European Union –- where the higher recycling rates and a cleaner energy mix make it a world leader – have outlined three areas where the plastic industry can contribute in the fight to contain global temperature rises to 1.5% in line with global goals outlined in Paris agreement on climate change.

Full Circularity is Key

The first objective is to increase recycling globally. This is certainly an area where other types of plastic can learn from PET which boasts the highest recycling rates for polymers.

“Aggressive application of renewable energy, recycling and demand-management strategies, in concert, has the potential to keep 2050 emissions comparable to 2015 levels. In addition, replacing fossil fuel feedstock with biomass can further reduce emissions and achieve an absolute reduction from the current level,” writes Zheng.

However, reaching full circularity is without question the single lever that can solve both plastic’s waste and greenhouse gas emission problem most effectively.

“Recycling all end of life (EoL) plastics under 100% renewable energy allows 77%, 84% and 86% reductions in life-cycle GHG emissions from fossil fuel-, corn- and sugarcane-based plastics, respectively,” says Zheng.

In this field, PET remains in the lead when it comes to recycling with recovery rates as high as 92% in countries like Belgium. Levelling up to these levels across the globe and across all polymer types is arguably the most effective way to curb plastic’s footprint without losing the hidden benefits of the material in the fight against global warming.

“Nine of ten countries with established DRS, in Europe, have achieved sorted for recycling rates of 83% or higher,” according to Petcore Europe. “These systems result in varied performance – it is currently estimated that the worst performers result in sorted for recycling rates of 22% while the best reach rates of 75%. This is with the exception of Belgium, who reports a sorted for recycling rate of 92% despite not having a DRS scheme in place.”

The challenges of achieving this are considerable, however. An in-depth study by SYSTEMIQ for Plastics Europe, ReShaping Plastics, points to some of the difficulties ahead.

One scenario outlined by SYSTEMIQ, applies proven circular economy technologies and approaches together and at scale, within feasibility constraints and points to an affordable and achievable pathway for reducing GHG emissions and plastic waste disposal by 33% and 46% respectively by 2030 compared to 2020 (and even more by 2040/2050), and for achieving 78% circularity in the European plastics system by 2050.

“The analysis indicates that this scenario requires major shifts in policy, public behaviour change, and an investment of approximately €160- €180 billion between 2020 and 2050,” says Yoni Shiran, Program Director and Partner at SYSTEMIQ.

“Circularity levers are the fastest, most affordable, most effective, and most reliable method of reducing GHGs and waste disposal in the system available to stakeholders today, and most of their benefits can be achieved before 2040. Circularity also has a positive impact on employment levels, although some workforce reskilling may be required.”

“How close the system comes to transformation will depend on the level of leadership shown by key decision makers across all stakeholder groups,” says Shiran.

“The adoption of circular economy approaches across the plastics value chain can drive a 33% reduction in GHG emissions and a 46% reduction in waste disposal by 2030. It is both affordable and achievable within technical constraints but requires an ambitious combination of both upstream and downstream solutions. A new plastics system is within reach but will require bold action. It needs industry, public sector, investors, and civil society to come out of their “trenches” and collaborate in a deeper way based on a shared fact-base,” says Shiran.

Gains from a Renewable Energy Mix

The second objective as mentioned by Zheng is to shift the energy matrix towards renewable energy sources. The doubling of plastic’s carbon footprint in the last 20 years stems directly from the dominance of coal-fired power plants in some of the world’s largest plastic producing countries.

The Coalition on Materials Emissions Transparency estimates that the emissions of a common PET bottle can be cut by 56% if it is made with renewable energy. It is estimated that each KG of PET currently produces 3.4 kg of carbon dioxide equivalent. This would fall to 1.5 kg CO2e if the energy matrix used to produce the material were renewable.

“On average, switching to 100% renewable energy would reduce life-cycle GHG emissions from plastics by 62% in 2050, assuming 4% yr growth in demand,” writes Zheng.

Plastic is not functioning in a vacuum, however, and the shift to a greener energy mix will also benefit other materials, reducing notably the competitive advantage PET holds over aluminium and glass, reducing the differential to zero, or less, in the case of aluminium.

McKinsey & Co’s Helmcke, writes. “Because PET emissions in 2050 will be primarily driven by emissions from waste to energy and since its production process is less energy intensive, PET emissions will decrease relatively slowly compared with aluminium and glass, leading to a narrowing of PET’s GHG advantage. In fact, under the 2050 best-case scenario (a 1.5° pathway), aluminium cans have lower GHG emissions than PET bottles.”

To achieve this ambitious goal as soon as possible, Simbiotiq suggests that the European Union will need to invest €160- €180 billion between 2020 and 2050 in retrofitting existing and future production capacity to help reduce emissions.

Bioplastics & Carbon Capture Needed for Net Zero

Full circularity would lead to very little need for the level of virgin fossil fuel feedstocks – still accounting for more than 90% of annual plastic production but a third improvement would be required on the path to zero: the replacement of fossil-fuel based polymers by polymers produced using alternative sources.

The shift away from fossil fuel stocks towards renewable feedstocks completely would enable the industry to move to zero.

“Emissions could be cut in more than half by using renewable energy sources, however, a 93% reduction from the baseline could be achieved by 2050 if renewables are combined with the use of bioplastics,” says Zheng.

Investment in agriculture as a source of fuel stocks for polymers like ethylene however comes with other environmental and social concerns including water usage and competition for land with food stocks.

SYSTEMIQ outlines what it calls “The Net Zero Systems Change Scenario” as a potential pathway to a net zero emissions plastics system by 2050.

As well as the greening of the energy mix and an increase in circularity to 78%, SYSTEMIQ’s most aggressive scenario expands the role of hydrogen and the use of alternative feedstocks from both biological sources and CO2 capture.

“Exclusive dependence on biological sources of carbon feedstock is risky, but by expanding the use of captured CO2 (enabled by a clean hydrogen economy), the plastics system could strategically reposition itself as a carbon sink and enabler of climate change mitigation,” says Shiran.

There are companies already positioning themselves in this innovative space, including Lanzatech, Newlight Technologies and Avantium. Technologies that capture carbon and convert greenhouse gases like methane and carbon dioxide into feedstocks for the industry, are still largely unproven but provide a regenerative and possibly redemptive pathway for plastic from perceived problem to undisputed solution.

Interested in contributing to getting plastic to net zero, the AdaPETation Network is keen to bring solutions together to encourage greater collaboration.

If you’re working on something that puts PET at the service of life we’d love to hear from you. Please join the network and share with us your initiatives.

Share it

Useful Links

THE HISTORY OF PLASTIC

Throughout the history of plastic, PET has been crucial in keeping food fresh with lightweight and durable packaging solutions that have helped reduce food waste for almost a century. Learn all about the invention of plastic and the important role it has played feeding people and saving the lives of humans and elephants in the adaPETation® timeline of the history of plastic.