NREL is a national lab that is supported by the Department of Energy in the United States and my team works on lots of different things but I’m part of the group working on turning waste materials into more valuable compounds so whether that is energy, some parts of NREL are focused on renewable energy or whether that is taking waste materials and making those into more valuable commodity chemicals so there is an incentive to renew the materials we are using into new things and continue the cycle.

In this particular case my focus is on taking polyethylene terephthalate and finding ways to degrade that and turn it back into its starting compounds so it can either be used again for PET plastic without use of properties or qualities that would be ideal for consumer goods or turning it into something entirely new. So instead of having no outlet for that to go to, that’s the kind of goal and we study several other things including PET and in this context we’re part of a broader consortium that’s called B.O.T.T.L.E – which is Bioptimized Technologies to Keep Thermoplastics Out of Landfills and the Environment, which is a bit of a mouthful so instead the name BOTTLE is also a lot easier to go with.

It’s a big team of researchers at both industry and national labs, government labs and academic labs, across the United States and there are some partners overseas. We are also involved with researchers in the UK and the partnership is constantly growing. The consortia kicked off in the middle of last year (2020). There was some groundwork in place.

ADAPETATION: What problem are you and the team trying to solve and how important is this research in trying to close the loop on plastic production?

It might be easy to give you a little bit of background on PET to give you some context. I won’t claim to be an expert on all of the steps in this process. PET is one of the most highly produced synthetic polymers that we use in consumer goods, industry and packaging, industry and textiles so that’s a lot of markets to cover and it’s just extremely versatile and easy to produce.

The starting materials all come from petroleum feedstocks, they all come from refined petroleum feedstocks but the building blocks are terephthalic acid and ethylene glycol. So if you squint a PET chain it could almost look like some of the natural polymers we find in the environment so the research that we are doing is looking at biological solutions to breaking down this synthetic polymer and either recreating the starting components or starting those into something totally new so my specialty is in biochemistry so I am mostly focused on the enzymes that would do this.

Enzymes are machines that do virtually everything that you could imagine in biology. In your body you have gazillions that are doing all the functions that you would need to survive and in every living organism there are similar systems but in this instance we’re looking for enzymes that have some sort of affinity or specificity for these types of synthetic polymers and they can break the bonds that form that chain releasing these small components – either those are small chunks or go back to the monomer that started – so instead of needing to draw from that petroleum feedstock over and over again you could use the material that was created initially and re-generate the same material without loss of quality.

I keep going back to this loss of quality because while PET while it is the most abundantly used polymer right now it is also the most recycled polymer right now so if you think about recycling in some parts of the world this is the easiest to handle and it also has possibly the largest financial impact so if you can collect pretty pristine drinking bottles for example many of those can be recycled mechanically.

The problem with mechanical recycling is that it involves crushing the material and shredding it, melting it down and converting it into a new product, but the new products are of a lower quality they don’t have the same mechanical properties or thermal properties that the original material did so you are downgrading the material over time and I think statistically when you look at the larger system materials might get recycled once maybe less than that and only about 20% of the materials that are made in this polymer class either actually enter a recycling stream so we have a large resource that we can tap into and approach this in a different way, potentially that would result in even more recovery of the original material meaning that you have to dip into other resources even less.

ADAPETATION: It’s interesting to see how nature has been brought back into the equation after being kept out of the loop for the last 70 years. Could you tell us a little bit more about Mother Nature’s role in this discovery?

I’m going to start in the middle of the biggest story because this field has been in existence for a little longer than our team has been working on it. In 2016, a group from Japan identified and published a story that made a very big splash in not just academic literature but also the public media that they had identified an organism growing in a recycling facility in Japan that can use at its sole carbon resource for this organism a PET bottles. So it was somehow living on thes old plastic piles and it didn’t have any other food source so if you think about that its really remarkable because it means that this organism found itself in a place short of other nutrients to eat and it evolved over a really quick period of time to be able to eat a synthetic polymer and if you think about all of our uses of plastic the goal is that biology doesn’t break them down.

All of our materials that we have developed are incredibly useful in large part because we can use them over and over again or because they have a lot of durability and resistance to all of the things that we might do to them but that of course encompasses all plastics and for certain applications that’s not necessary so in this case we have a material that is really resistant to biological activity but instead this organism found a way to do that anyway and I don’t want to confuse anybody that this organism only wants to eat PET, if there were other organisms around it would certainly want to eat those instead but in the lack of other dinner it made something worthwhile, right.

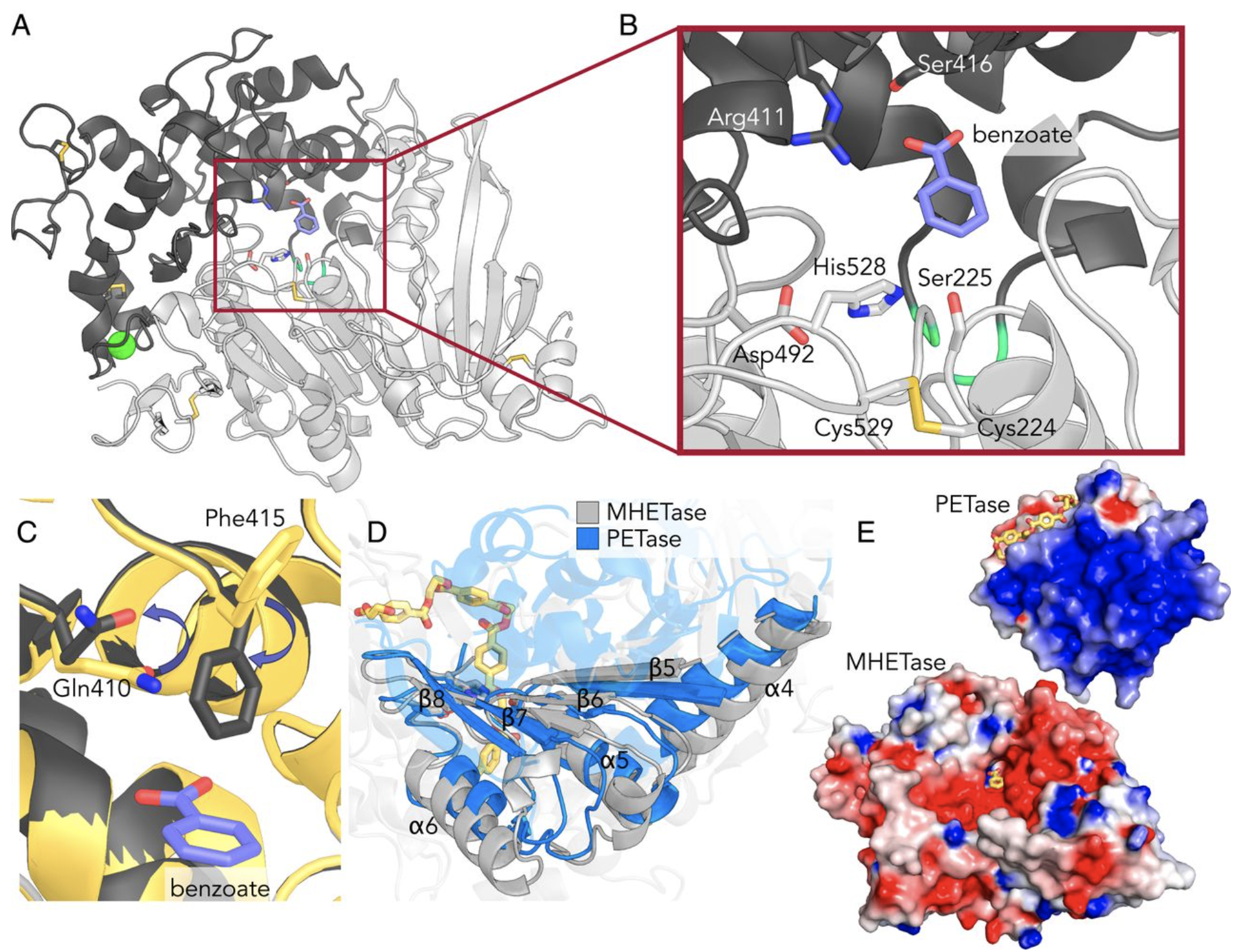

The way that it did this was to probably, this is hypothetical, but is likely what happened is that this organism evolved from a different type of food source that looked similar had similar chemical linkages and it co-opted those same proteins that would break down those natural polymers to be really specific for this synthetic polymer and the two enzymes that do that are PETase and MHETase – in biochemistry we add the ending ase onto the name to show that its an enzyme that breaks down something so PET is the PET plastic so we have the first enzyme that breaks down PET plastic and the second enzyme in the pathway breaks down small monomeric chunks that come off of that in the breakdown product so the final resulting compounds are terephthalic acid and ethylene glycol which is what you started with to make the material.

This organism can use this as food so it has the catabolic pathways to eat terephthalic acid and ethylene glycol so it’s not like exactly eating PET it’s doing something to it to crush it up and make it into edible little morsels but that is really impressive, especially when you are thinking of the grand scale of biology because PET wasn’t invented until the 1940s so 1940 to 2016 isn’t really very long on the evolutionary timescale to think about a new adaptation and so it was able to do this quickly possibly because the materials look similar enough that it could easily adapt but it also means that its not perfect it’s not a fast process its a slow process which means that these organisms don’t get a lot to eat.

They have to work pretty hard for their meal. So the reason our group got interested in this is because this isn’t the only enzyme that has ever been reported to work on PET plastics there are several others. That’s why I’m saying that we’re starting in the middle but our group got interested in this because this one is very specific to PET.

We wanted to understand what might be the structural differences in the protein sequence that might give it this capability to be really specific for this polymer. So the field in general probably could give its origins more to the early 2010 and 2012 when these other enzymes were identified that were specific to cutin and suberin, these are materials that are part of plant mass.

Cutin is the waxy layer that covers leaves and gives some water and permeability to plants so invaders find it more challenging to get into the plant and it also keeps the water balance at equilibrium so cutin is part of that process so the waxy layer on the leaf and suberin is much like cork in a cork tree. These are complex natural polymers that look in some of their linkages a lot like synthetic polymers so that is what was found in those earlier studies that there are enzymes that exist that can do this but they are not specific to PET they just happen to do it and some of them do it quite well so it’s just building this body of literature and understanding of what might make an enzyme happy to break down a PET polymer and how do you then moving forward how do we make that better. How do we encourage that process to be faster or more durable or to work on more and more types of PET that come from different types of processes that created the material to begin and so this is where the research is going.

ADAPETATION: It all sounds more than promising so how has the research progressed since the first discovery in 2018?

Our group got interested in PETase because of that specificity question that its evolved specifically for PET so in collaboration with John Mckean’s group at the University of Portsmouth who are wizards at structural biology and our group at NREL and several others, there’s always a lot of collaboration on these projects, we explored what we could do with PETase and made some targeted mutations to see how that would change either specificity or reactivity and what we found was that this double mutant so it has two point mutations so two amino acids in the whole sequence have been changed and what this actually did was to make PETase look a little more like those cutanases that had been discovered previously and what this did was allow an improvement in some cases in the degradation rate so we found that even more degradation occurred when you use this.

That was awesome in terms of a first step as we’re still talking about a really new field here and having the structure in hand helps us to understand how an enzyme might work and what we might be able to do to make it work better and that is also to give it comparison between all these different natural variants that would occur so moving on from there we then looked at the second enzyme in the pair and that is mPETase this is also from this organism that was discovered but the second enzyme its strikingly similar to the PETase except that it has a full extra portion of the enzyme that makes kind of a hat or a lid on top of the reaction site and this enzyme is quite particular to the smaller components so it still does a similar reaction where it will break and ester bond but it’s only going to work on this MHET compound so wanted to know if this could be optimized or changed and so we looked at a lot of mutants of this enzyme as well but because they worked together and this is a system or a team we also wanted to figure out how each of those enzymes was participating in this partnership there be some circumstances in that by using the two together we could improve performance.

So in 2020 we also published a study describing how this partnership is really important and that activity and the amount of breakdown that you can see when you see PETase alone is quite a bit less than when PETase and MHETase are in activity together in the same reaction but to go a little bit further we also tethered those together so they would make a complex so this is a kind of chimeric protein and when tethered together the performance is even better so this is all really still preliminary work and all of our reactions are done at really small scale but what this is doing is starting to show the details of how we could implement different strategies for using enzymes to create larger processes or larger scale industrially relevant processes for handling PET waste.

ADAPETATION: How do you see this being applied to the problems the world currently faces for plastic pollution and what do you think will be the main challenges to applying this solution at scale?

This is definitely still a work in progress but as part of our group at NREL we have technical and economic analysis teams so they do analysis on all of the factors that you would need to consider in order to create a process at scale.

That includes what would the feedstock need to look like, where would it come from how would you build a facility, what would be involved in that, what would the process look like, where would the materials go at the end and the idea with this is that not only can you glean this data from other processes that exist and make some assumptions along the way to build this for a totally new application but it also tells you where areas are really expensive to make into reality and to help guide what research still needs to happen to make it an economically viable process and we have this technological and economic analysis underway and it should be available to the world soon.

It’s in the works. What it shows is that there are really some very impressive results coming out of this there are circumstances where we could get close to cost parity or really close to the same cost for an enzymatic recycling process of PET to the virgin production of PET and part of that is not just the money side of it – you need to have some kind of economic incentive for the world to adopt a process on a global scale but there are a lot of other benefits to this process especially in terms of greenhouse gas emissions and energy consumption and water consumption that look really different along the supply chain.

So this is all work that has been happening the results at least at this preliminary stage are extremely promising that while we may not quite be at that stage where we can implement this and there are some groups in the world that could be much closer than we are, the process itself could be economically viable so the next steps are a lot about scale up and finding the appropriate feedstocks and then finding appropriate buyers from the other side to make a new product from the materials.

ADAPETATION: From a scientific perspective can you share with us how we got to the situation we are currently in and how are you and your team applying systems thinking to the challenges the world faces with plastic pollution for instance?

It’s hard to give a full overview from only a scientific perspective as this also affects my life personally but starting in the 1940s when it was obviously very hard to envisage how the world would change over time but with the advent of these quick, cheap and safe materials to package food and to use for all the applications we can think of. Every piece of clothing or device you own probably has some plastic in it including this phone that I am holding right now.

It impacts on every aspect of our life and this isn’t just for convenience but also for health and safety so medical devices, the medical field has been able to accelerate its ability to treat disease and to with stability move through all sorts of things that used to be considered deadly that are no longer even thought to be a problem really a quick solution and all of this has really revolutionised the way we do almost all of the activities in our life and in more developed countries i think this is taken for granted because it’s so pervasive but this is extremely important in the developing world as well where materials that have been replaced they make a big difference to the quality of people’s lives the sanitation aspects, everything so we are in a sticky place right now with the accumulation of the materials we’ve made.

They don’t go away in the way natural materials do and part of that is because there aren’t many organisms that have evolved to be able to handle them and in some ways you can almost look at that as being a matter of time but we are not at a point when we can handle the inputs to continue to increase when the outputs don’t ever disappear so while that is a bad situation to be in I don’t want to demonize plastic as the worst thing to ever been created.

There’s so many societal and health and technological impacts that it has had that have been crucial in the development of the globe at this point and so I think a lot of that opportunity and possibility is what the original creators were envisioning all those decades ago and that is probably what has driven the trajectory of where technology has gone especially in terms of the development of new materials and I think at this point we’ve had long enough to gaze backwards and see where we made mistakes and how we could have foreseen this if we had taken the time to think about it in that context and so moving forward I think a really noble goal for all materials that we would make in the future and that is why i keep saying that we could reuse these processes to either re-make PET or to make something new and the goal for all new plastics would be that they have an end-of-life in mind.

There’s a strategy that could be applied that would break those back down into components either that being if they were to escape into the natural environment then they would become food for natural organisms there and it wouldn’t persist in the environment for decades to centuries so I think that is where we find ourself now that those things weren’t thought about and that could be shortsightedness and it could just be that the opportunities for the uses were so much greater than that we didn’t think about running out of space or having this problem.

So I think in the future that would be the most effective way to handle any new technologies or materials that are created so in my mind we’re kind of coming at this from several perspectives but we have a problem with this right now and the technologies that I’ve been working on with enzymes to break down certain polymers that’s to address the problem that we have right now that would be for all plastics that are generated today so we have a process to deal with them so that tomorrow we aren’t in the ocean or in the natural environment or filling up our landfills unnecessarily.

But we also have all of that material that is in the ocean or in the landfills and that’s totally another set of problems that need to be addressed and while this technology could have some promise there I don’t see how we will be able to go in and recover all those resources to apply it but there is a chance for that right as this develops and it becomes more economically viable that could become the situation from a bioremediation perspective though there is a lot of challenges of introducing organisms that have been modified, materials that have been modified in some way and in some way of controlling that so that you only do the things you want, where you want would be really important to keep in mind.

Those are two big problems that we have but in the future I would hope that we would be able to start to develop materials that have and end of life in mind so if you have a food package that needs to last 15 minutes before it becomes waste then that shouldn’t be a material that could persist in the environment for a thousand years. It doesn’t need to be that strong or durable it could be a less resistant material and still provide the same sanitation and containment properties so I think that is the direction that we should be moving in.

ADAPETATION: Where do you draw optimism from when you see how the science community is bringing together solutions to the problems of plastic pollution and how fast do you think we may have the solutions in place?

It is really exciting to be a part of this and there’s a lot of people in the global community in science and industry working on the same thing and it’s starting to see movement and a collective effort towards this goal so I do draw a lot of reassurance that we can come together as people of the globe to address this problem from a lot of different aspects so the work that I am doing is one of many different approaches or strategies.

I do not have any allusion that my research will be the silver bullet that fixes all things I think this is one of many strategies and approaches that could be used to address this problem and it could be used as a foundation to move into other types of plastics as well so we’re talking about just one of a very large collection of really challenging materials to break down and recycle and so I think what encourages me is that I know and get to hear about a lot of other creative strategies that are out there that also have a lot of opportunity and potential for addressing this.

I think it will be a collection of all of these that really does truly lead to some change and I don’t think that if we put all of our eggs in one basket. So enzymatic depolymerization is really cool. Obviously that is what I go into every day at work and I could talk about it all day but there are so many other strategies that could also be really beneficial especially from a scale up perspective.

There are so many materials that are so degraded that we won’t get the starting materials out of them, they’ve been messed up too much by the sun but they need an end of life. They need to go somewhere and then there will also be materials that won’t be susceptible to biological breakdown for example.

A lot of the really common plastic like polyethylene and polypropylene, these things that make plastic bags for example while there be some biological agents that could be active on those they would be likely be extremely inefficient so if I am proved wrong on that I would be so excited to see that process take place but I I think there will be more thermal or chemical glycolysis things like this that are a better approach to this and also creative strategies that I can’t even think of right now.

But because we’ve started this global conversation it’s got a lot of people thinking about this, really young people right now that aren’t yet in a position to be scientists and just by starting the conversation and by making it a topic of awareness then people can start thinking about it and making it a priority as we move forward so that’s what I’m really optimistic about while we may come up with an idea now we can’t as scientists create a technology to save ourselves we have to do that all together and I like that it’s become one of the topics on the horizon to think about.

THE HISTORY OF PLASTIC

Throughout the history of plastic, PET has been crucial in keeping food fresh with lightweight and durable packaging solutions that have helped reduce food waste for almost a century. Learn all about the invention of plastic and the important role it has played feeding people and saving the lives of humans and elephants in the adaPETation® timeline of the history of plastic.