An interview with Reiten Cheng, Founder of Polyformer, on converting PET bottles into just about anything through 3D printing.

Our fifth finalist for PET Heroes 2024 is Reiten Cheng, the inventor of Polyformer, a beautiful device created to provide global creators with a ready supply of filament for 3D printing machines made from PET bottles.

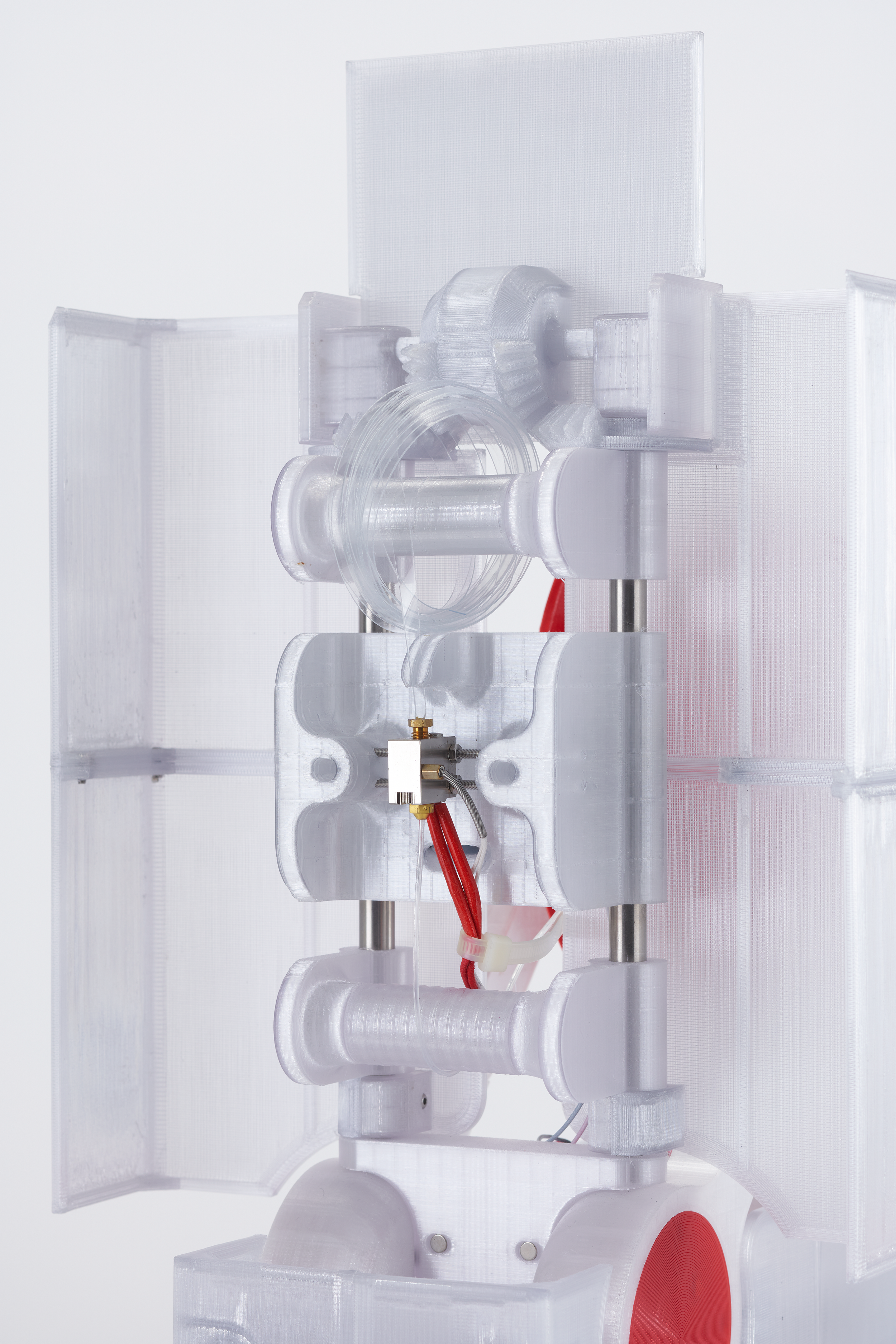

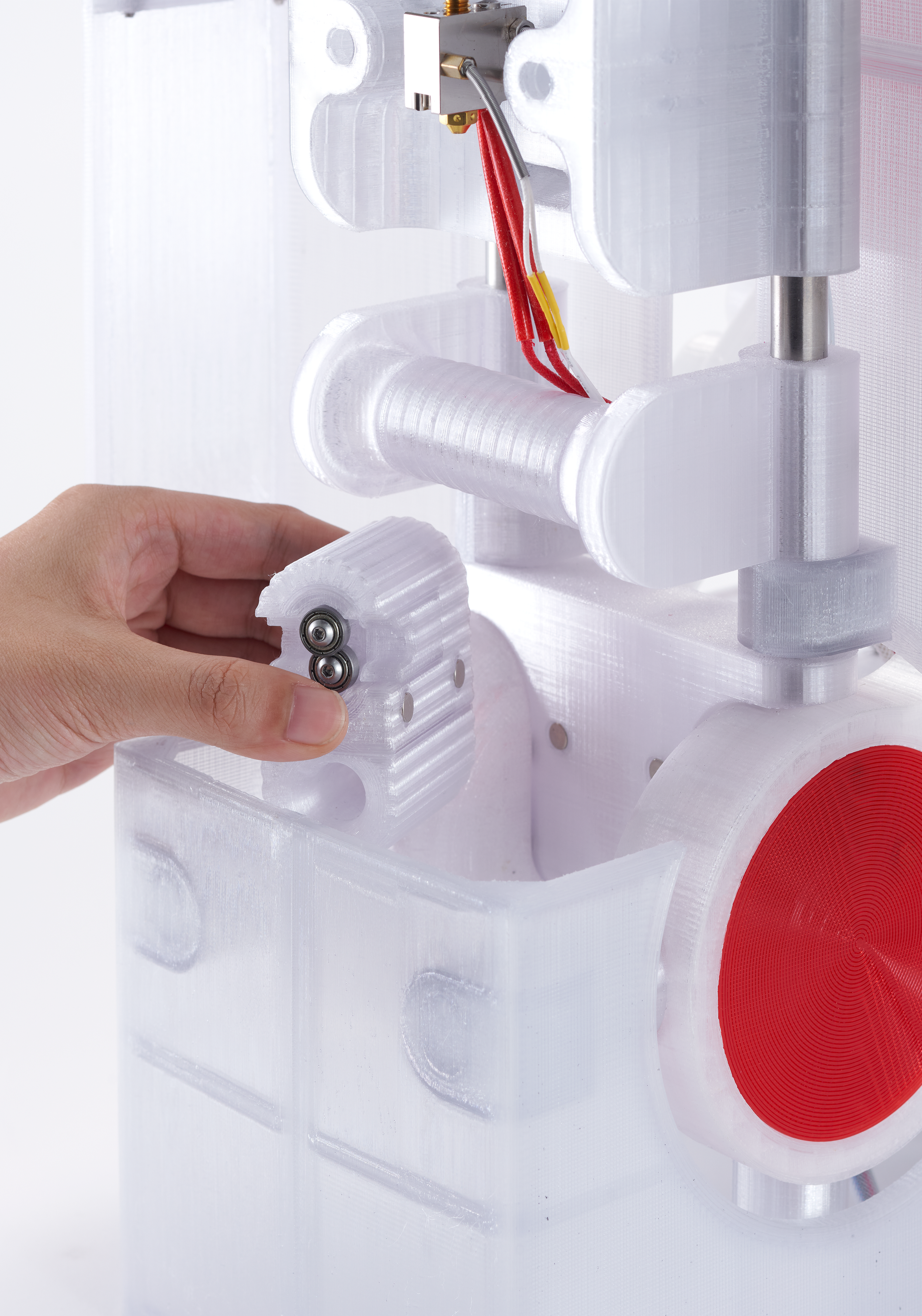

Polyformer is a 3D-printed, open-source machine that recycles PET bottles (90% of plastic water bottles are made from PET) into filaments for 3D printers. Polyformer is designed to be built with mostly 3D printed parts and easily obtainable components commonly found on 3D printers. Which means that most makers can build it themselves. The modular, open-source architecture allows users to easily swap out parts and modify the machine to their liking.

Cheng, an industrial designer with a focus on physical UX, believes that through rapid and iterative prototyping, thorough user testing, and carefully analyzing the process, opportunities could be discovered to improve the physical experience.

He talks about a strong desire to become an inventor with the ability to create something impactful for our era. As someone on the autism spectrum, he has encountered significant challenges in pursuing paths that align with his personal logic and he says his struggle has extended throughout his life, manifesting in his search for a suitable engineering discipline that effectively addresses real-world problems from a human-centered perspective.

His efforts aimed to simplify the printing process, infuse Polyformer with both functional and aesthetic qualities, and discreetly incorporate elements that enhance the user experience. He takes pride that his unique perspective as an individual on the autism spectrum enables him to discern intricate details beyond surface-level observations and persistently pursue endeavors that align with his sense of purpose.

Five Minutes with Reiten Cheng: Reshape, Recreate, Reproduce. 3D Printing with PET bottles

Welcome to “Five Minutes with Reiten Cheng,” where we dive into the mind of an industrial designer who believes that plastic has a crucial role to play in solving some of the most pressing problems we face as a species. Today, we had the pleasure of talking with Reiten Cheng, the brilliant mind behind Polyformer, a groundbreaking initiative that aims to convert plastic waste into a host of other useful products through 3D printing technology.

Q: Could you share with us the light bulb moment for Polyformer, how you came up with the idea of the concept?

A: Reiten Cheng: The lightbulb moment for Polyformer came when I realized that plastic waste management was a significant concern, and traditional recycling methods weren’t always economically viable for many corporations and countries. Drawing inspiration from my experience in open source projects and 3D printing, the idea to decentralize recycling through a collective community effort emerged as a solution. This moment of inspiration led to the birth of Polyformer, which aimed to turn common plastic waste into something useful and efficient using 3D printing technology.

Q: What problem is Polyformer solving with regards to plastic pollution?

A: Reiten Cheng: Polyformer addresses the problem of plastic pollution and the challenges associated with plastic waste management. Specifically, it provides a solution for recycling PET bottles into filament for 3D printers, thus reducing the environmental impact of plastic waste and promoting sustainable practices in manufacturing.

Q: How does Polyformer work?

A: Reiten Cheng: Polyformer has developed a special tool that cuts PET bottles into long and consistent ribbons. These ribbons are then pulled through a hotend system, where they are thermoformed into 1.75mm 3D printer filament. This filament can be used on any 3D printer, allowing individuals to create a wide range of products while utilizing recycled plastic.

Q: What made you want to go down the open source route?

A: Reiten Cheng: I have been involved in open source projects for quite some time, and the idea of easy distribution and decentralized recycling resonated with me. By making the technology open source, anyone with access to a 3D printer can create their own Polyformer units. This approach fosters collaboration and empowers individuals and communities to take action in recycling and manufacturing.

Q: How do you see the future of Polyformer?

A: Reiten Cheng: Currently, Polyformer is being used by individuals all over the world, from Africa to Southeast Asia. The community is growing, with around 4,000 members actively engaged in the Polyformer Discord community. Looking ahead, our vision is to scale Polyformer and overcome challenges such as resource access and technical limitations. We aim to raise awareness and education about the benefits of Polyformer, empowering local entrepreneurs to use 3D printers and build businesses around sustainable manufacturing practices.

Q: What are the obstacles and challenges that you currently face in offering your solution at scale?

A: Reiten Cheng: Scaling Polyformer comes with its own set of challenges. One of the potential obstacles is access to necessary resources and funding for further development and distribution. Additionally, raising awareness and educating communities about the benefits and usage of Polyformer is crucial. We also need to overcome technical limitations and refine the technology for broader adaptation, such as reducing filament usage and the number of parts needed to produce the machine. Ensuring proper waste collection feedstock for the recycling process is another important challenge we are working on.

Q: Who is currently using Polyformer and what are they producing with the recycled PET bottles?

A: Reiten Cheng: Polyformer is being used by users from all over the world, from countries like Africa, Argentina, France, and Southeast Asia. People are actively using the recycled materials to feed into 3D printers and create various products. These products range from phone stands and fans to headphones and even computer mice. Polyformer not only provides the raw material but also enables individuals to create products that may be difficult to obtain in their respective countries.

Q: Do you have any examples or a community where people can see the creativity unleashed by Polyformer?

A: Reiten Cheng: Absolutely! Interested individuals can join our community Discord, where they can explore the possibilities of 3D printing and see the creativity unleashed by Polyformer. On platforms like Thinniverse and printables, users have uploaded their designs for various 3D-printed products. The potential for creation is boundaryless, with people designing and printing everything from practical everyday items to unique personal creations.

AdaPETation: What impact do you believe design can have in transitioning to a better world?

A: Reiten Cheng: Design plays a crucial role in transitioning to a better world by creating innovative solutions to complex problems. In the case of Polyformer, the design of the 3D-printed open source machine allows for decentralized recycling and manufacturing. By designing for sustainability, efficiency, ease of use, and modularity, we empower individuals and communities to take action and reduce their environmental impact.

JOIN THE MOVEMENT

If you are looking for more information on the equitable approach of Reiten Cheng sign up to receive more information about the Plyformer and other inspirational changemakers sign up to receive weekly updates.

Share it

The Other PET Heroes & Useful Links

THE HISTORY OF PLASTIC

Throughout the history of plastic, PET has been crucial in keeping food fresh with lightweight and durable packaging solutions that have helped reduce food waste for almost a century. Learn all about the invention of plastic and the important role it has played feeding people and saving the lives of humans and elephants in the adaPETation® timeline of the history of plastic.